Production processes comply with the technical documentation

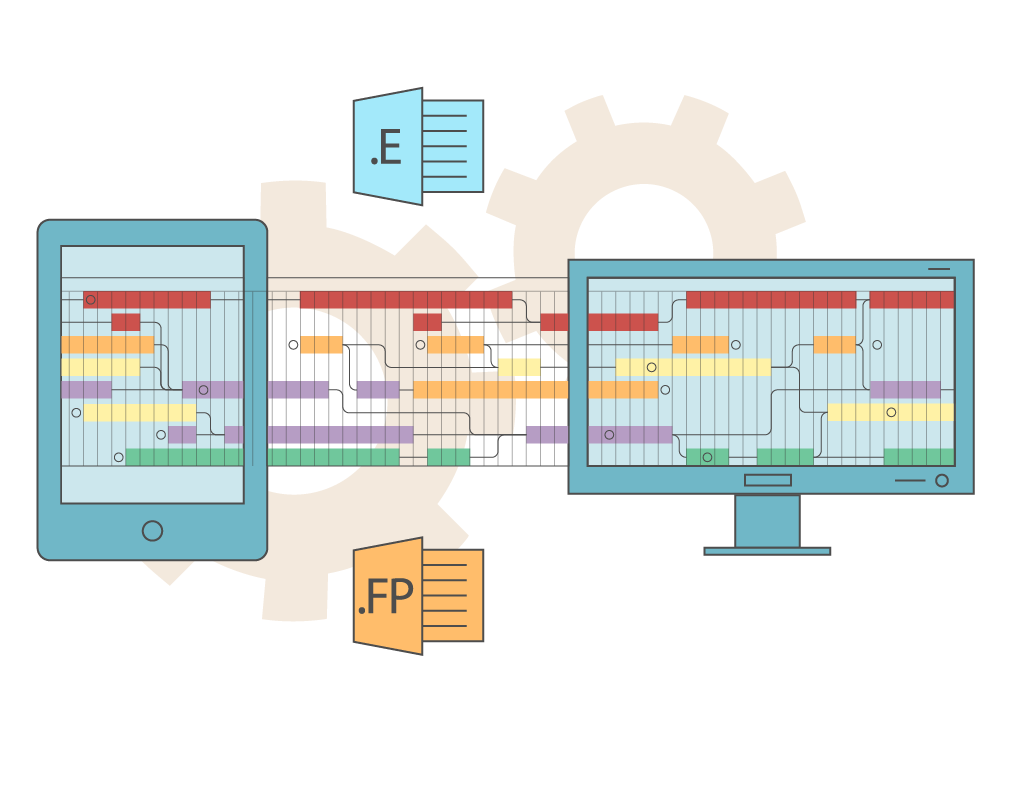

Results of all control operations are recorded and stored

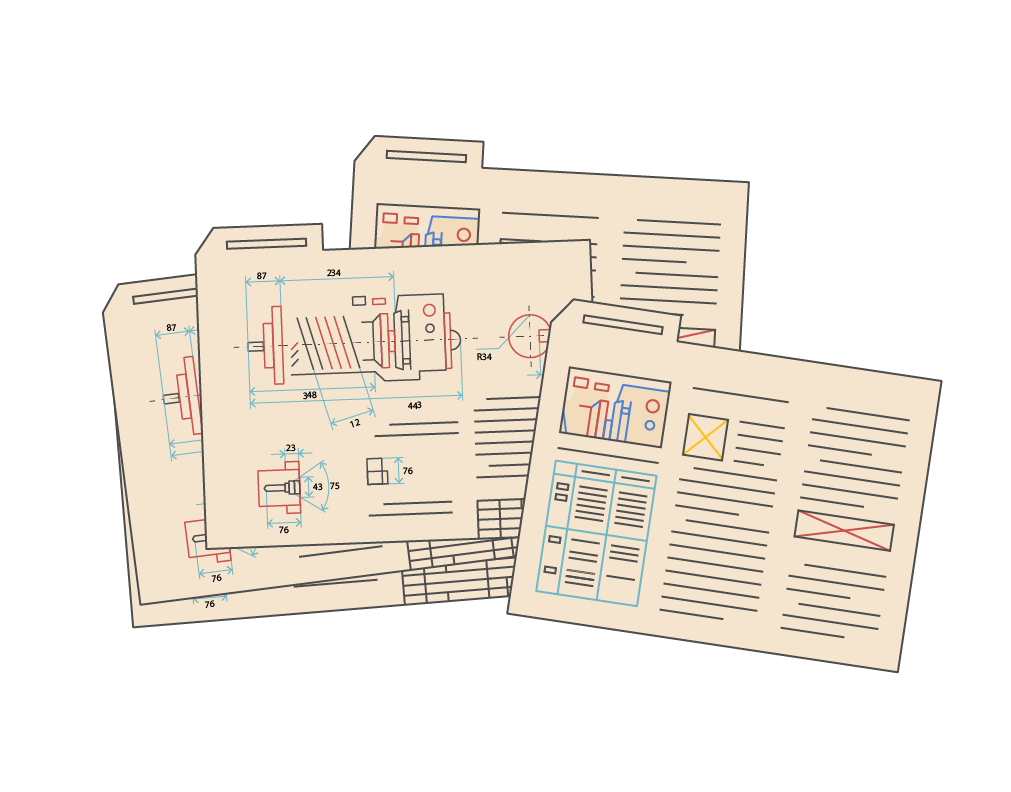

Technical documentation is kept up to date

Up-to-date documentation is available at workstations

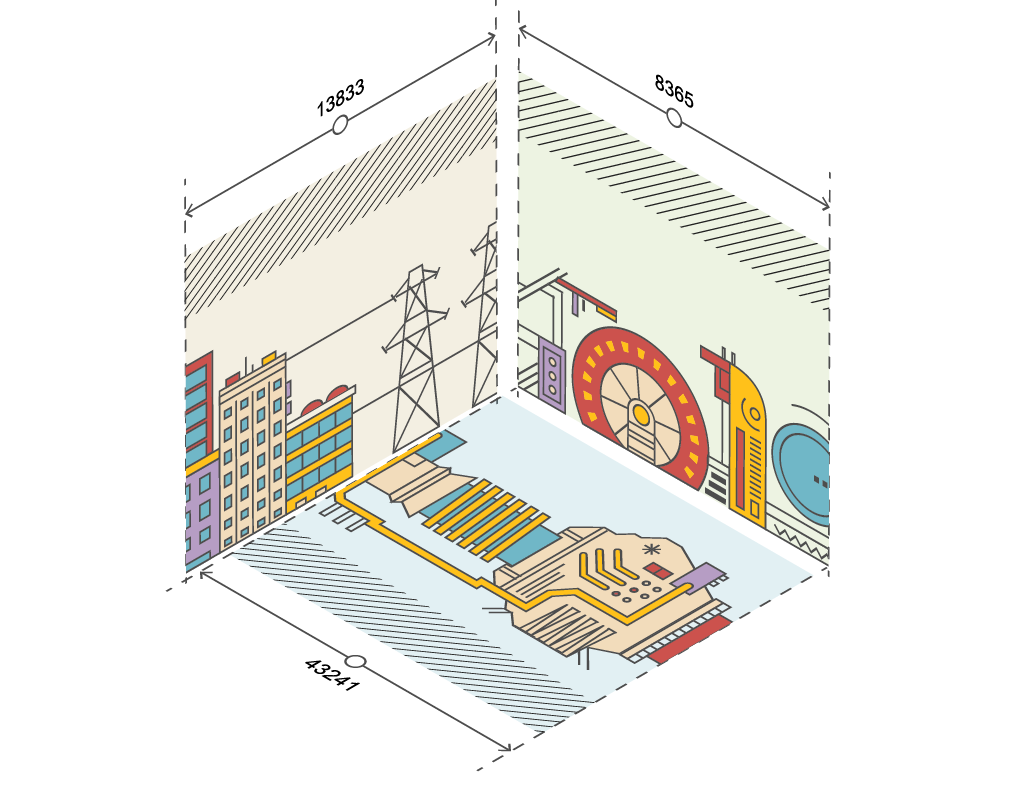

The tasks of storage, exchange, access, synthesis of management information is solved by the information system.

Search for any “black boxes” in your business process

Issue missing technical documentation

Release executor’s primary documentation

Organise storage of the results of control operations

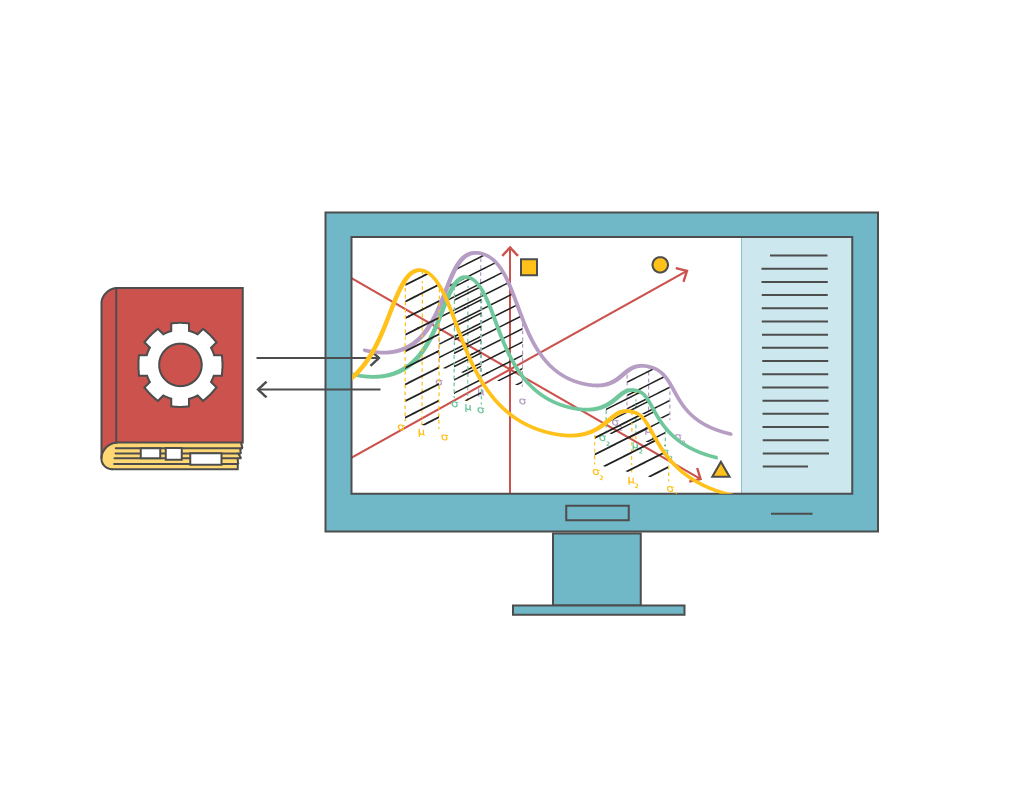

Manage information synthesis

Evaluate the possibility of process optimisation

Prepare automation of decision-making management

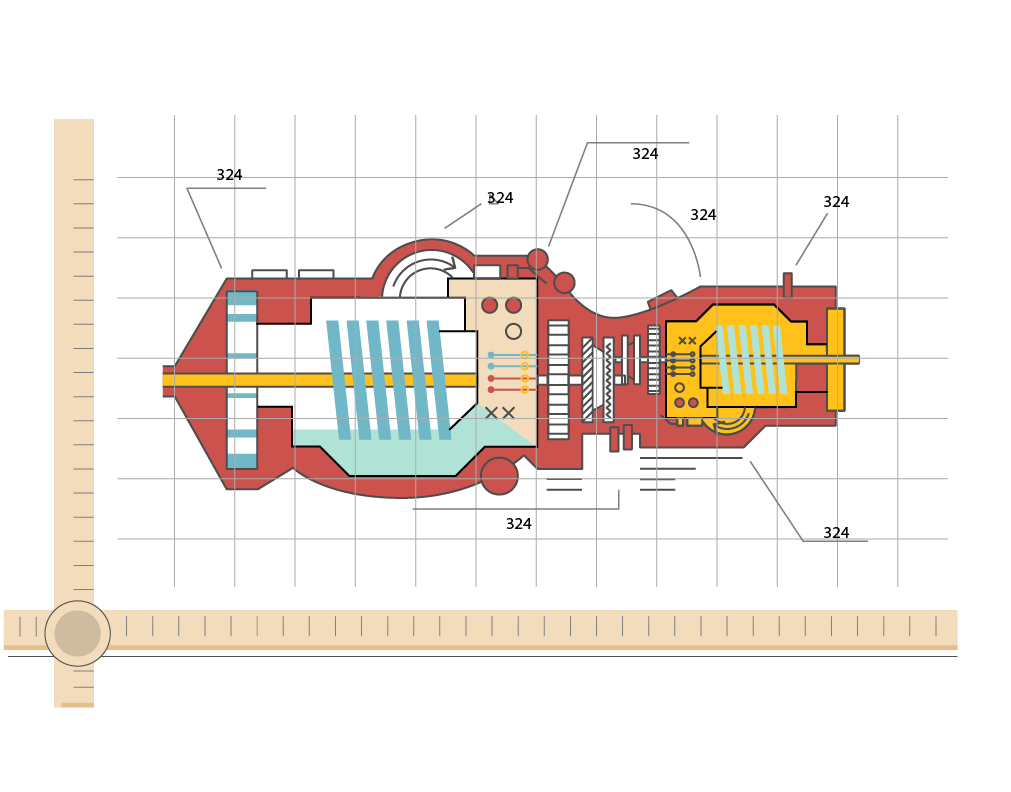

Parametric modelling of the object by means of CAD with consecutive deepening of decomposition.

Creation of regulations for handling and storage of primary production documentation.

Automation of adjustments of production processes with regard to changes in the criteria for assessing key indicators.

The documentation is produced in accordance with the parametric Object Model.

Primary production documentation is produced to record the results of control transitions.

Definition of a list of key indicators of the production process.

Parametrization of management impact limitations (technological, infrastructural, industrial safety).